DEVICE FOR ECONOMY AND OPTIMAL FLOW OF CARBON DIOXIDE GAS / ARGON

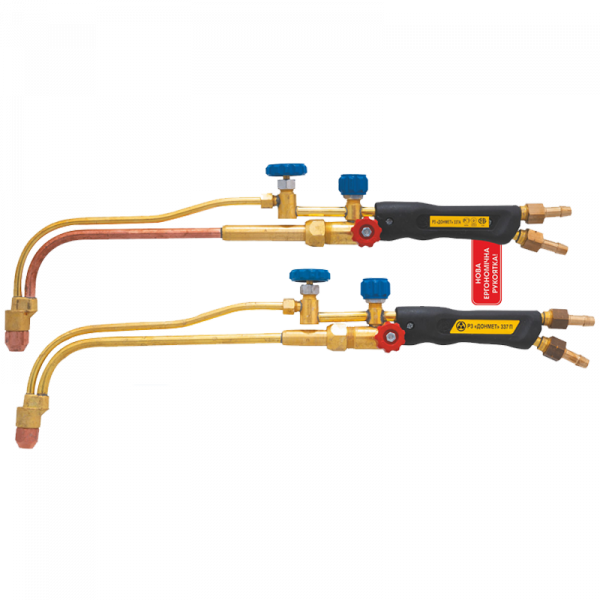

Optimizer of lightweight design. The lighter version is devoid of additional adapters for connecting to the hose rupture and holes in the body for connection to the welding machine.

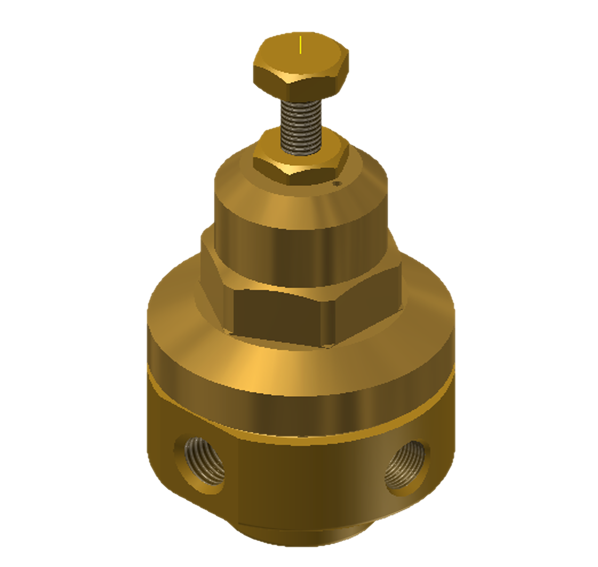

For arc welding in shielding gases, pressure regulators with a working pressure of up to 10 bar are used.

With the termination of welding, excess gas pressure (usually 3.5-6 bar) is formed in the hose between the pressure regulator and the welding machine.

After continuing welding, this excess volume of gas is instantly discharged to the atmosphere. At the same time, the amount of excess gas can be 6 times higher than at the time of welding. However, for optimal protection of the welding bath, a maximum pressure of 1.0 bar with a flow rate of 25 l/min is required.

These costs can be prevented by the “DM Optimizer” attachment to the pressure regulator

► Installed at the outlet connection unit of the pressure regulator;

► Saves up to 50% of shielding gas;

► Reduces the frequency of changing cylinders;

► Reduces the costs of transporting cylinders to the gas station;

► Saves gas purchase costs.

“DM Optimizer” provides:

– optimal flow of shielding gas from the first seconds;

– absence of a turbulent splash at the beginning of welding;

– twice as many seams with the same amount of gas.