Torch «DONMET» 263, hereinafter referred to as the torch, is designed for laying facing roll roofing and waterproofing material, as well as for surfacing bituminous roll material for waterproofing various structures.

The torch is alsoi used for drying reinforced concrete panels, levelcrete and brick laying.

Used gas fuel: propane-butane (Р).

The torch basic features conform with ISO 9012:2011.

TECHNICAL SPECIFICATION

| Gas fuel consumption with tip №4Р,

(7 nozzles Ø 48.5) |

18,8 – 25,1 kg/h

(12,7 – 17,4 m3 /h) |

| Gas fuel pressure with tip №4Р

(7 nozzles Ø 48.5), kgf/сm2 |

2 – 3 |

| Rate of heat flow with tip №4Р,

(7 nozzles Ø 48.5), kW |

315,7 – 429,2 |

| Working width, mm | 1000 |

| Torch weight no more than, kg | 5,2 |

Note: one kilogram of liquid propane-butane mixture generates around 500l of gas..

SPARE PARTS (as per customer’s order)

| Item | SKU |

| Sealing ring 005-008-19 | 341.808.00 |

| Sealing ring 006-010-25 | 230.011.00 |

| Sealing ring 008-012-25 | 142.006.00 |

| Sealing ring 010-014-25 | 344.009.00 |

| Sealing ring 013-017-25 | 337.006.00 |

Can be supplied dissembled.

DESIGN AND PRINCIPLE OF OPERATION

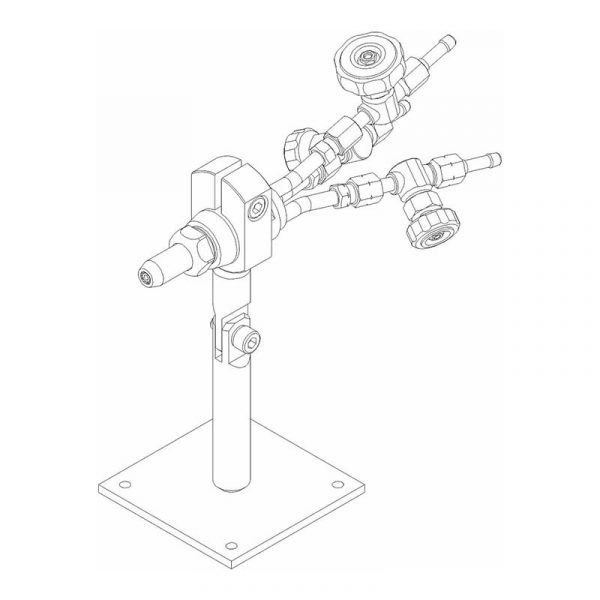

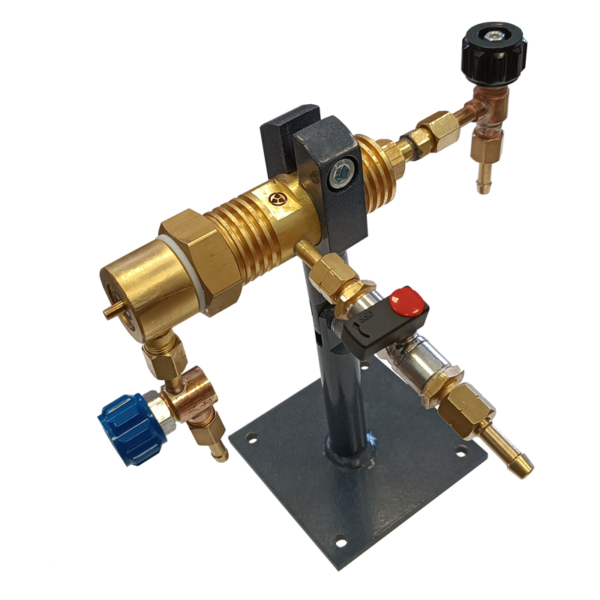

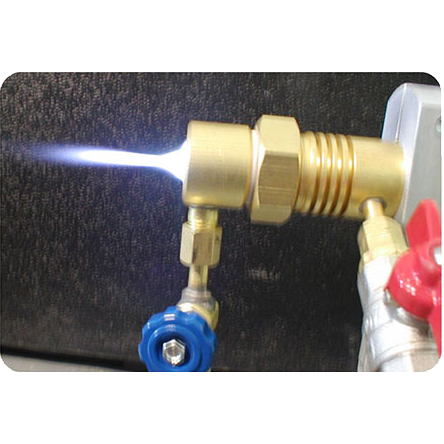

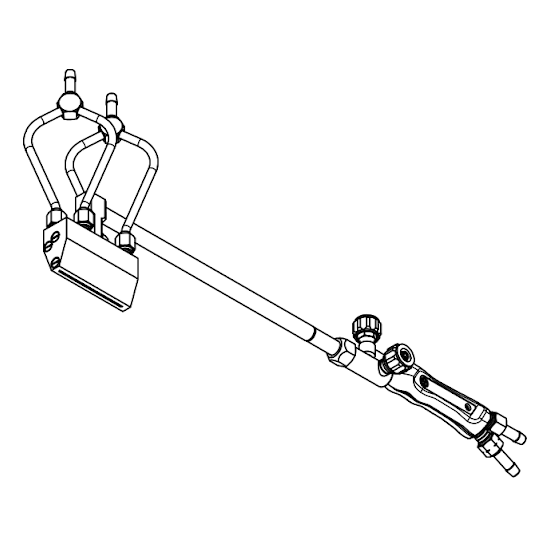

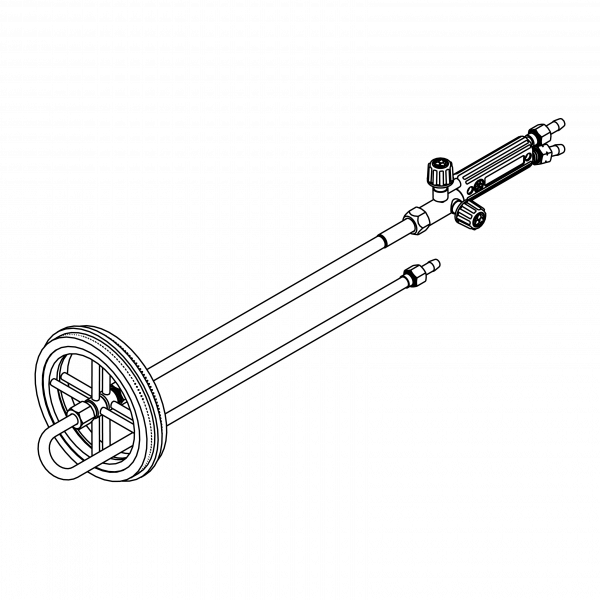

Manual air-gas low-pressure torch consists of a shank, a gas tube and a cart. The torch shank consists of:

а) gas flow regulating valve unit;

b) flame length adjustment key in the form of a lever valve (for switching from stand-by flame to working flame)

c) gas fitting.

The tip is intended for connecting the shank to the cart.