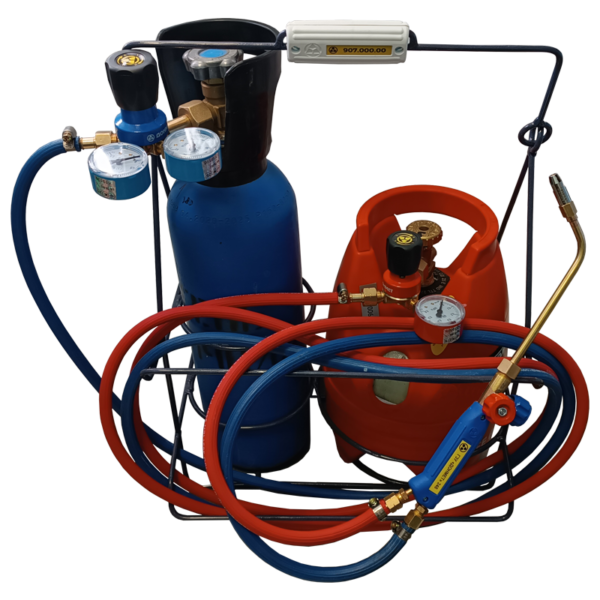

Economical autonomous portable station for cutting low carbon steels up to 20 mm, brazing or heating.

– basket (order № 907.100.05)

– disposable propane cylinder 330-400g 7/16″-28 UNEF (epi-gas) (order № 907.054.00)

– oxygen tank V=5 l (order № 907.033.00)

– adapter 7/16″-28 UNEF (order № 962.500.00)

– oxygen regulator BKO-50-O DM (order № 067.000.00)

– cutting torch DONMET 132P MICRO (order № 132.000.06)

– flashback arrestor for oxygen (order № 950.000.22)

– hose OXYGEN ISO EN 559 2MPa; 3,2 mm; L=4 m

– hose PROPANE ISO EN 559 ; 2MPa; 3,2 mm; L=4 m

– hose clamp (order № 284.052.00)

– nipple assembly Dy3,2 (order № 947.000.00)

– nut М16х1,5 (order № 330.004.04);