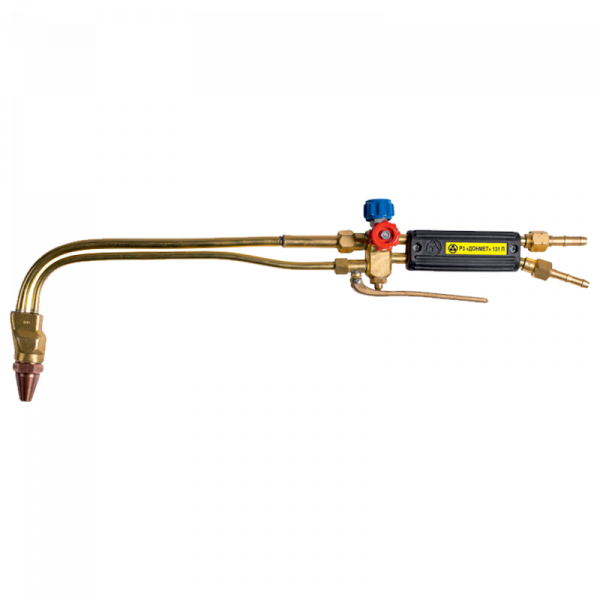

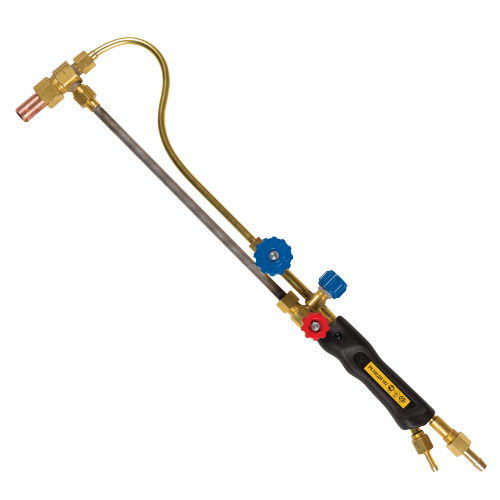

Cutting torch DONMET 503 for manual surface scarfing

Broadband cutting torch for manual surface scarfing

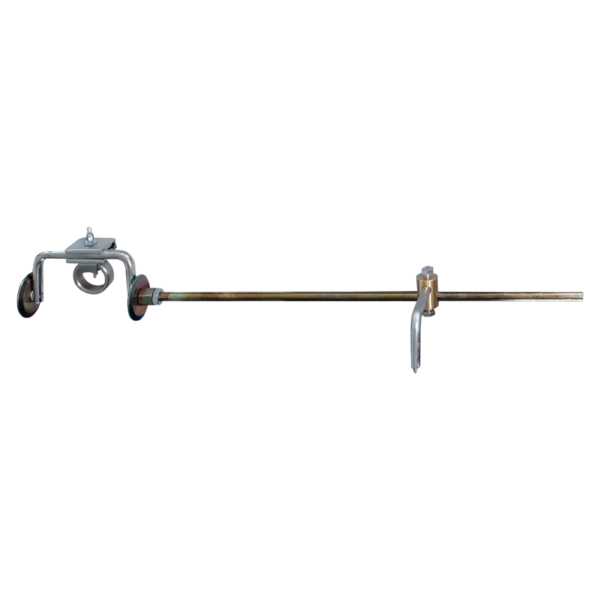

Purposed for: flame scarfing of surface defects on steel ingots, shaped castings and rolled ferrous metal products. It can be used for flame gouging of separate grooves as well as surfaces.

It has proven itself at such enterprises as PJSC “ArcelorMittal Kryviy Rih”, JSC “Zaporozhsteel”:, PJSC “Azovstal Iron and Steel Works”, PJSC “Mariupol Integrated Iron and Steel Works named after Ilych”, CJSC “Donetsksteel Iron and Steel Works”.

Used gas fuel: natural gas (methane).

The cutting nozzle is made of copper and can be removed and replaced. On client’s demand it can be supplied with the cutting oxygen orifice diameter either 8mm or 10mm. To reduce the part’s wear as a result of friction against the surface of the metal being processed, the preheating nozzle is cladded with a wear-resistant material.

We perform customization of the cutting torch to the individual conditions of production (length, head bending angle, etc.)!

| TECHNICAL SPECIFICATION | |

| Inlet pressure of oxygen, MPa (bar) | 1,0-1,4 (10-14) |

| Inlet pressure of methane, MPa (bar) | 0,09-0,12 (0,9-1,2*) |

| Consumption of oxygen, m3/h | 250-300 |

| Consumption of methane, m3/h | 13-16 |

| One-pass track width, mm | up to 80 |

| Track depth, mm | up to 10 |

| Speed of gouging, m/min. | up to 12 |

| Cutting torch length no more than, mm | 2000 |

| Cutting torch weight no more than, kg | 3,0 |

| Hose inner diameter for oxygen | 8 |

| Hose inner diameter for gas fuel | 8* |

| Used gas fuel | methane |

| Gas-mixing type | special |