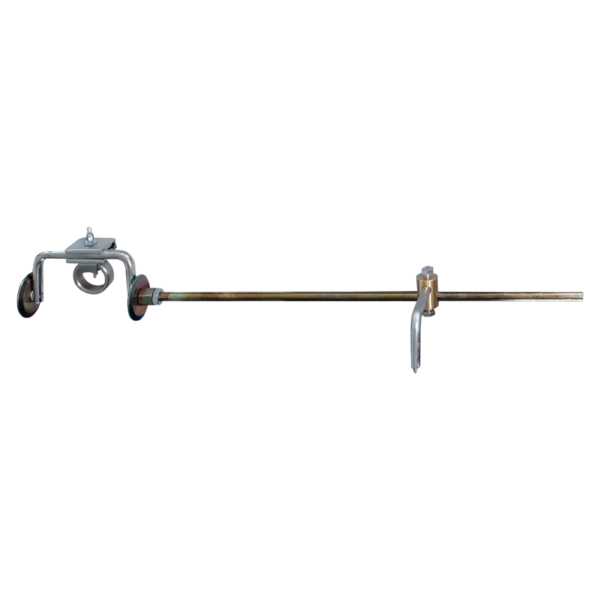

Designed for: hand oxy-gas parting cutting of scrap metal, topping of low-carbon steel ingots up to 700mm thick.

Used gas fuel: natural gas (methane).

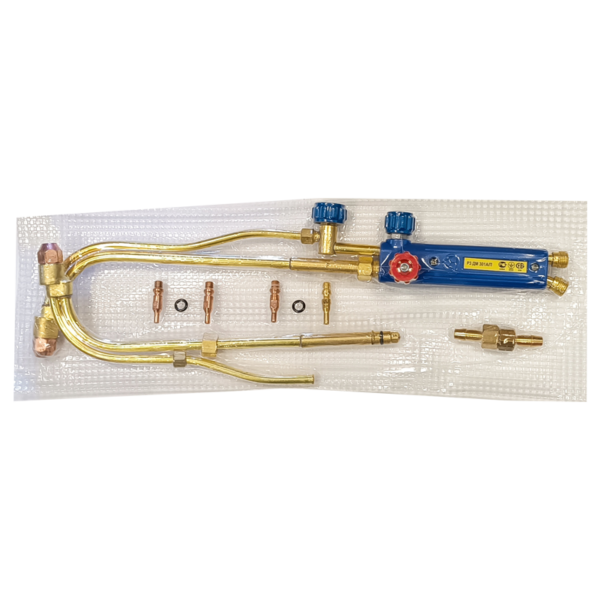

Design features:

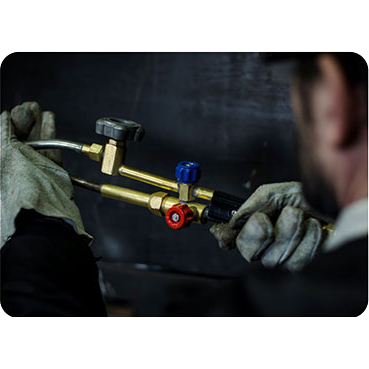

– quick opening and closing of the cutting oxygen valve due to the triple thread at its stem;

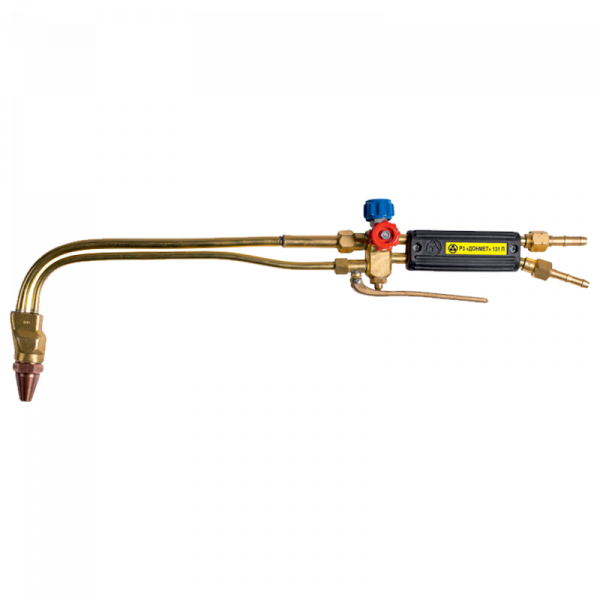

– preheating and cutting oxygen nozzles made of copper;

– replaceable cutting nozzles (central channel diameter – 5-6mm);

– tip tubes made of stainless steel;

– operation allowed at oxygen pressure 6-7 bar;

– solid valve stems of stainless steel. Service life of more than 15 000 cycles;

– direct flow head;

– backfire proof due to an elaborate design of the mixing chamber;

– comfortable aluminium pad;

– cutting oxygen knob from the cylinder valve.

| Inlet pressure oxygen , bar | 6-7 |

| Inlet pressure methane , bar | 0,7-1,5 |

| Consumption oxygen, m3/h | 41-120 |

| Consumption, methane, m3/h | up to 5 |

| Cutting thickness, mm | 300-700 |

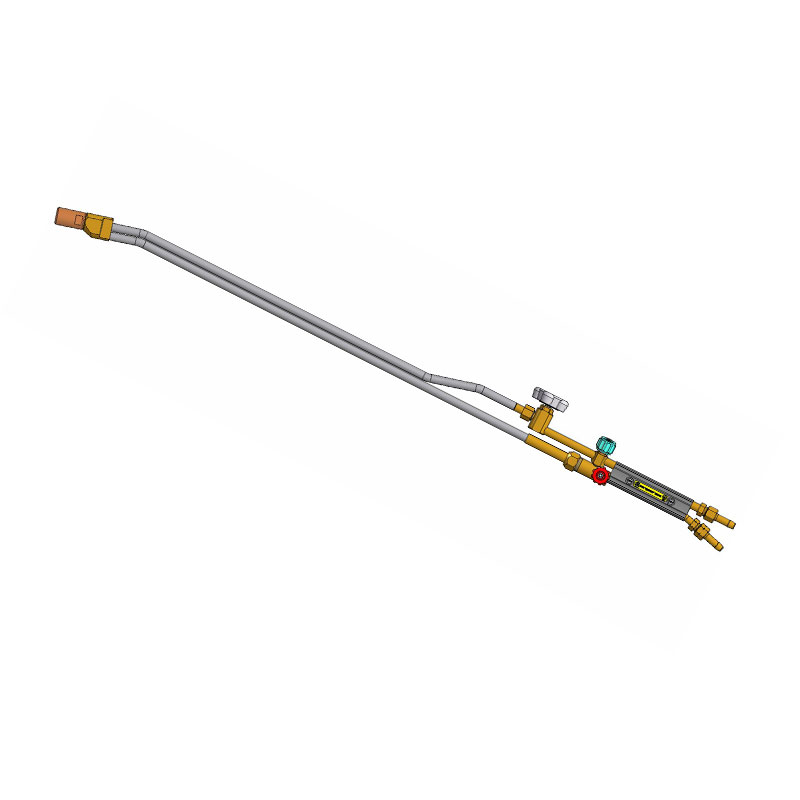

| Cutting torch length no more than, mm | 1130 |

| Cutting torch weight no more than, kg | 1,64 |

| Hose inner diameter | up to 10 |

| Connection unit thread oxygen, mm | М16х1,5 |

| Connection unit thread methane, mm | М16х1,5LH |