Designed for: preliminary treatment of slabs or blooms at metallurgy works, ensuring elimination of surface flaws (cracks, laps, skin inclusions) before rolling.

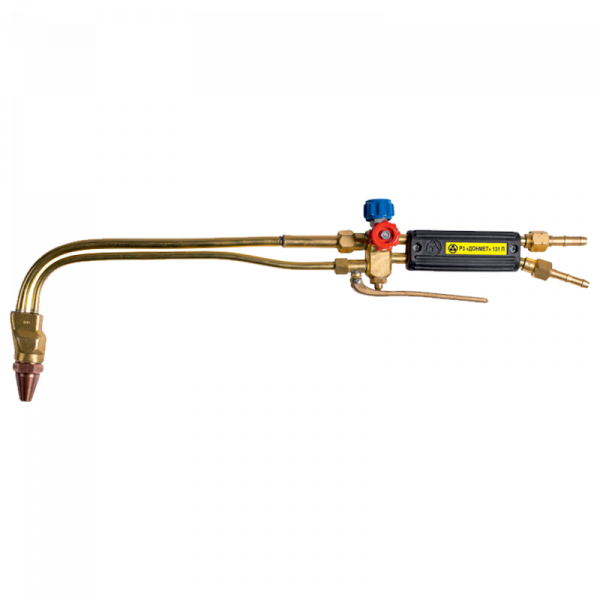

Design features: injection-type cutting torch with a special rod-feeding device that is meant to facilitate penetration and reduce consumption for metal preheating. The cutting oxygen lever is connected to the device. By pushing the lever the rod is automatically fed into the preheating flame and oxygen jet, the rod’s metal melts and hits the penetration point, thus the scarfing process starts almost instantly. A calibrated low-carbon steel rod 5mm in diameter is used as a welding consumable.

Used gas fuel: natural gas (methane).

ТЕХНІЧНА ХАРАКТЕРИСТИКА

| Inlet pressure oxygen, bar | 10-12 |

| Inlet pressure methane, bar | 0,9-1,2 |

| Consumption oxygen, m3/h | 250-300 |

| Consumption methane, m3/h | 13-16 |

| Grasp width, mm | up to 70 |

| Grasp depth, mm | up to 10 |

| Scarfing speed, m/min | up to 14 |

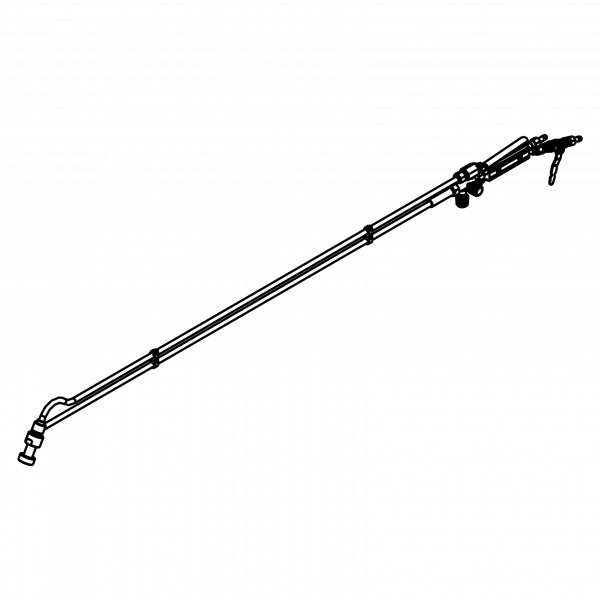

| Cutting torch working weight no more than, kg | 5,1 |

| Cutting torch length no more than, mm | 2300 |

| Connection unit thread oxygen, mm | G1/2 |

| Connection unit thread methane, mm | G3/8LH |