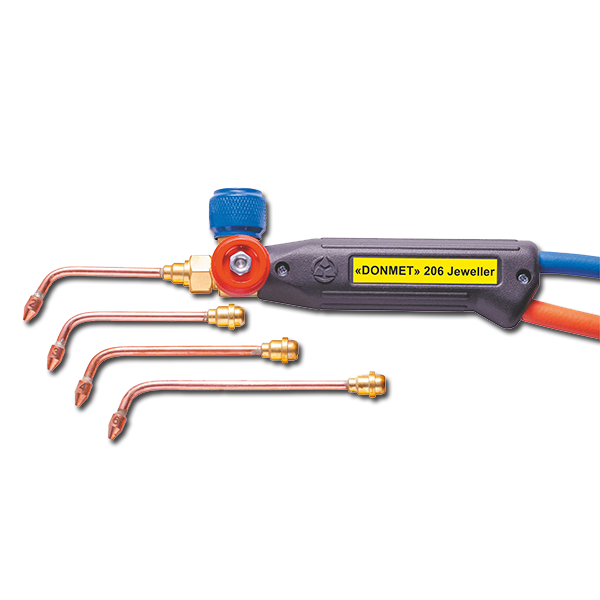

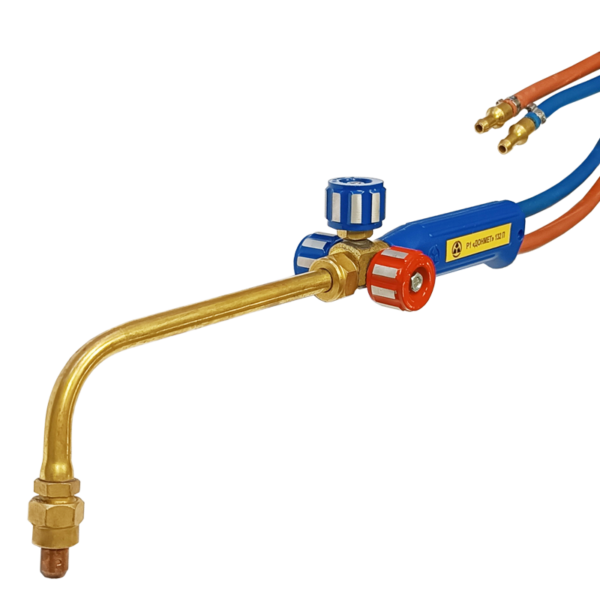

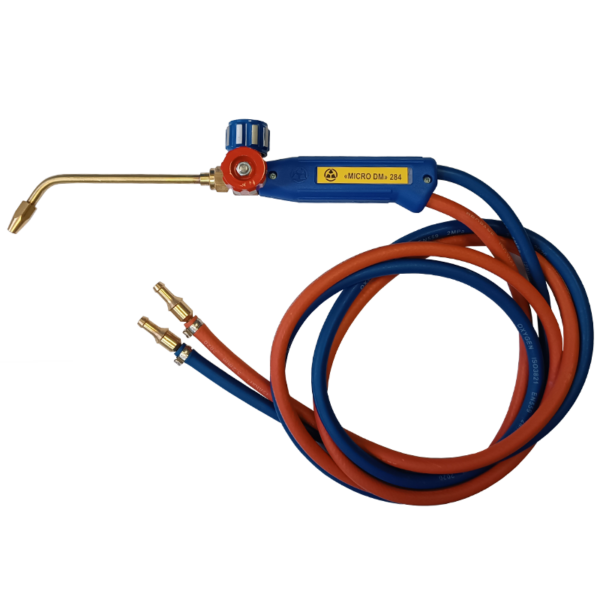

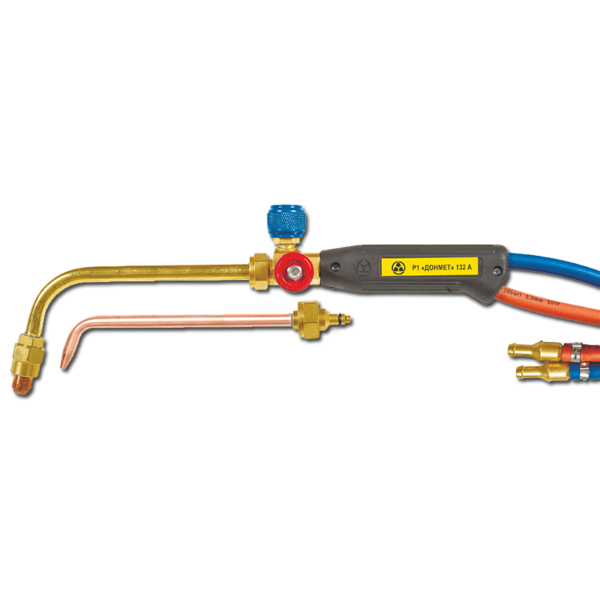

Portable gas cutting torch «DONMET» 132 P Micro

THE LIGHTEST AND SMALLEST GAS CUTTING TORCH ON THE MARKET

NO ANALOGUES IN THE WORLD!

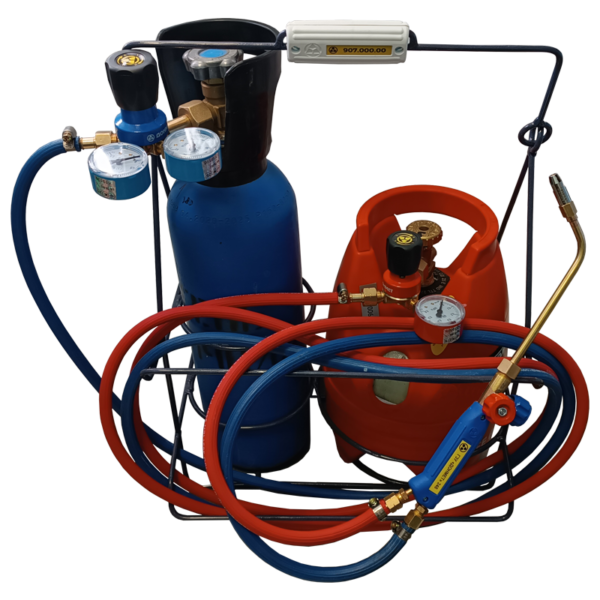

Makes a perfect combination with a portable gas kit!

The smallest and lightest gas cutting torch on the market that has no analogues in the world. Can be used as a torch for brazing and soldering of any metals and alloys due to a concentrated focused flame jet.

Cutting torch 132P Micro is designed for hand oxy-gas parting cutting of sheet and rolled metal of low carbon steel up to 20mm thick. Used gas fuel – propane-butane (P). Can also be used as a torch.

A perfect tool for making fine precision cuts with maximum control when cutting low carbon steel up to 20mm thick. Allows to quickly heat metal and start the cutting process. There are practically no temperature-induced deformations of thin metal due to precise heat input. Its small size makes it convenient to handle in all spatial positions.

Cutting torch 132P is the best choice for oxy-gas cutting off of a self-contained portable gas kit.

The cutting torch can be widely used in small production facilities, workshops, back offices and households as well as in field conditions with no power network, oxygen and propane being supplied from cylinders of any bulk.

Quickly and safely, without dust and noise, you will cut angles, channel bars, tubes and any other rolled iron used in household, construction and production.

Usability:

– cutting torch weight – just 300 g

– small size – length no more than 290mm

– convenient valve positioning allows to adjust the flame with one hand

– has the same cutting capacity as plasma cutting torches – minimal burn-off loss

– high cutting precision due to superior design of the nozzles

– does not melt metal surface when cutting thin metal

– cost-efficient

– metal spatter practically non-existent

Injection cutting torch DONMET132P MICRO is designed for manual oxy-fuel cutting of sheet and rolled low carbon steel up to 20mm thick.

Cutting torch basic features conform with the requirements of ISO 5172.

Version and used gas fuel: DONMET 132 P – propane-butane (P).

The cutting torch climatic version for operation at ambient temperatures from 20°С below zero up to 40°С above zero.

TECHNICAL SPECIFICATION

| Cutting capacity, mm | 1 – 8 | 8 – 15 | 15 – 20 | |

| Cutting torch “DONMET” 132 P Micro | ||||

| Inlet pressure, bar | oxygen (nominal) | 2.0 | 2.5 | 3.0 |

| gas fuel, P | 0,03-1,5 | |||

| Consumption, m3/h | oxygen, no more than | 1,41 | 1,65 | 1,89 |

| gas fuel, P, no more than | 0,3 | 0,32 | 0,35 | |

| Cutting torch weight, kg, no more than | 0,3 | |||

| Cutting torch length, mm, no more than | 290 | |||

| Hose | 6 /6 | |||

DELIVERY SET

| Item | Order № | Q-ty** |

| Cutting torch DONMET 132 P Micro 6/6 | 132.000.03 | 1 |

| Sealing ring 009 – 012 – 19 Ring SDU Р 2,8х1,5 RO 003х005х14 NBR |

344.008.00 025.304.00 |

1 1 |

| Manual | 1 |

SPARE PARTS (as per customer’s order)

| Item | Order № | Cutting thickness, mm |

| Cutting nozzle for 132 P Micro | 132.303.00 | 1 – 20 |

| Preheating nozzle for 132 P Micro | 132.302.00 | 1 – 20 |

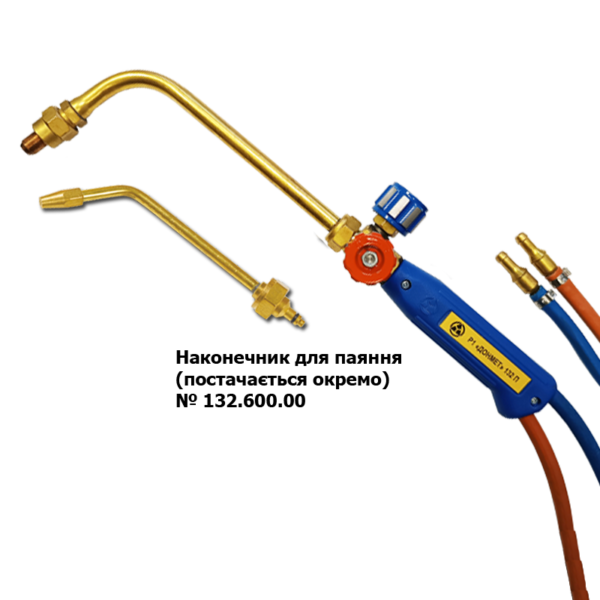

| Spare brazing tip | 132.600.00 | |

| Ring SDU R 2,8х1,5 RO 003х005х14 NBR | 025.304.00 | |

| Sealing ring 009 – 012 – 19 | 344.008.00 |

List of works performed with the cutting torch:

1. Precise straight cutting of rolled sheet metal

2. Precise contour cutting of marked-out sheet profile

3. Cutting in enclosed volumes and confined spaces

4. Parting cutting of sheet metal

5. Cutting of profile iron – pipes/channel bars/angle pieces/double-T pieces

6. Cutting of steel reinforcement

7. Cutting of rusted bolts, load pins, couplings when conducting repair works

8. Cutting when repairing car bodies in hard-to-reach places

9. Cutting when dismantling small metal structures (fences, enclosures, etc.)

10. Cutting holes in pipes of various sections and sheet metal

11. Cutting when using small-volume cylinders or portable gas kits

12. Heating products before forging

13. Heating products before bending (strip, pipe)

14. Heating products for subsequent hardening

15. Bearing heating before removal from the shaft

16. Flame leveling of sheet metal

17. Heating of “stuck” threaded connections for unscrewing

18. Heating of elements during the creation of metal sculptural compositions (design)

19. Heating elements during the creation of forged products ий

20. Local heating of the product surface

21. Soldering copper pipes during the installation of heating / underfloor heating systems

22. Soldering electrical cables

23. High-temperature soldering of ferrous and non-ferrous metal parts

24. Soldering of thin-walled ferrous metal tanks

25. Soldering of thin-walled aluminium tanks

26. Soldering of copper tracks during installation of multi-zone air conditioning systems VRF and VRV

27. Soldering copper or brass pipes to dilute oxygen and combustible gases

28. Non-ferrous metal smelting

29. Burning the paint-and-lacquer coating from metal surfaces

30. Burning soot from kitchen utensils

31. Supplied as part of portable gas kits

32. Calcination of parts

33. Scorching of wood to give it a vintage look

34. Warming up frozen locks, taps, water pipes thawing ice, etc.

35. Warm-up / calcination / heat treatment of welding seams

36. Quick lighting the fire

37. Fire marking

38. Heating before milling

39. Heating before surfacing

40. Surface heating during spray coating

41. Cleaning the metal surface of scale and other contaminants

42. Metal surface tinning