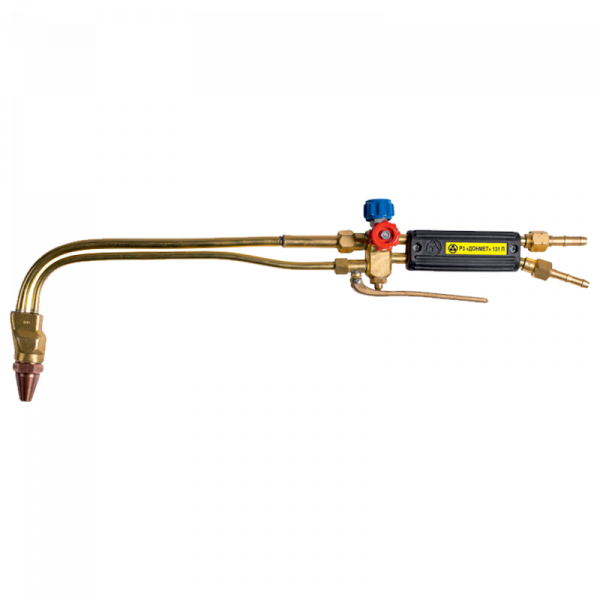

Water-cooled cutting torch for continuous casting machine.

Purposed for machine parting cutting of low-carbon steel sheet and rolled metal up to 300mm thick in continuous casting.

Design features:

– in-nozzle gas mixing;

– single-block nozzle;

– gas consumption adjustment via the gas-cutting machine control panel;

– water-cooling system.

It is successfully used at “TSA Steel-Group Ltd.” in Pavlograd, Ukraine.

This cutting torch is similar to the cutting torch “A.L.B.A” AOG 300 DR-91 code 04PM650.

Used gas fuel – natural gas (methane).

Recommended additional kitting: nozzles

| TECHNICAL SPECIFICATION | ||

| Nominal cutting thickness, mm | 200-300 | |

| Distance between the cutting torch and the item, mm | 100-140 | |

| Nozzle throat cutting channel diameter, mm | 1,8 / 2,5 | |

| Cutting oxygen inlet pressure, bar | 10-12 | |

| Preheating oxygen inlet pressure, bar | 1,5-2,5 | |

| Natural gas (methane) inlet pressure, bar | 0,70-1,5 | |

| Cutting oxygen nominal consumption, m³/h | 21-26 / 30-45 | |

| Preheating oxygen nominal consumption, m³/h | 14-19 | |

| Natural gas (methane) nominal consumption, m³/h | 19,0-25,0 | |

| Cutting oxygen inlet thread, mm | G1/2 | |

| Preheating oxygen inlet thread, mm | G3/8 | |

| Natural gas (methane) inlet thread, mm | G1/2LH | |

| Sleeve diameter, mm | 42 | |

| Cutting torch head thread | M28x2 | |

| Cutting torch length no more than, mm | 548 | |

| Cutting torch weight no more than, kg | 3,1 | |