Machine cutting torch “DONMET” 365

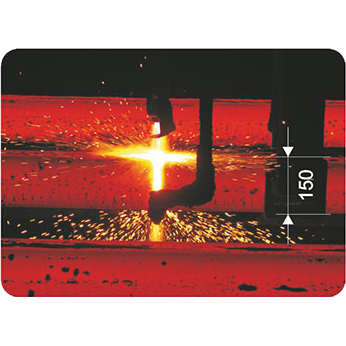

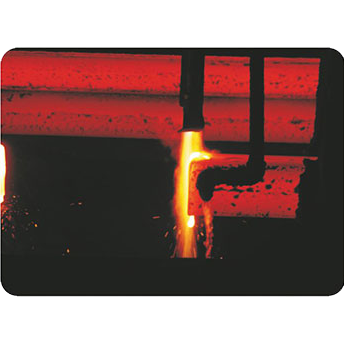

Designed for: machine parting cutting of hot low-carbon steel rough parts 50-500mm thick in continuous casting.

It has been successfully used at “ElektroStal Ltd.”.

Design features: in-nozzle gas mixing; single-block nozzle; gas consumption adjustment via the gas-cutting machine control panel; water-cooling system.

The cutting torch is compatible with and can work with the gas-mixing nozzles of such trademarks as Ge-Ga and A.L.B.A.

Used gas fuel: natural gas (methane).

TECHNICAL SPECIFICATION

| Cutting thickness nominal, mm | 200/ 300/ |

| Distance between the cutting torch and the item, mm |

100-400 |

| Nozzle throat cutting channel diameter, mm |

1,8/ 2,5 |

| Inlet pressure cutting oxygen, bar |

10-12 |

| Inlet pressure preheating oxygen , bar |

1,5-2,5 |

| Inlet pressure natural gas (methane), bar |

0,70-1,5 |

| Nominal consumption cutting oxygen, m3/h |

21-26/ 30-45 |

| Nominal consumption preheating oxygen, m3/h |

14-19 |

| Nominal consumption natural gas (methane), m3/h |

19 -20 |

| Casing diameter, mm |

50 |

| Cutting torch head thread |

M28x2 |

| Cutting torch length no more than, mm |

1000 |

| Cutting torch weight no more than, kg |

10,0 |