For cutting cast-iron and stainless steel up to 200mm thick

Purposed for: manual parting cutting of stainless steel, grey iron and other materials that cannot be cut by ordinary oxy-fuel cutting methods.

The nature of oxy-flux cutting is that a jet of gas fuel continuously carries powdered flux based on small-granular iron powder (grain size 0,02…0,04mm) to the cutting area. While burning iron generates additional heat, lowers the concentration of alloying constituents in the reaction zone and thins the dross, thus facilitating its removal from the cutting zone.

Delivery set contains:

– flux batcher with an adjustable swirling-type mixer (flux tank of 20kg capacity) equipped with a safety device and a flashback arrester;

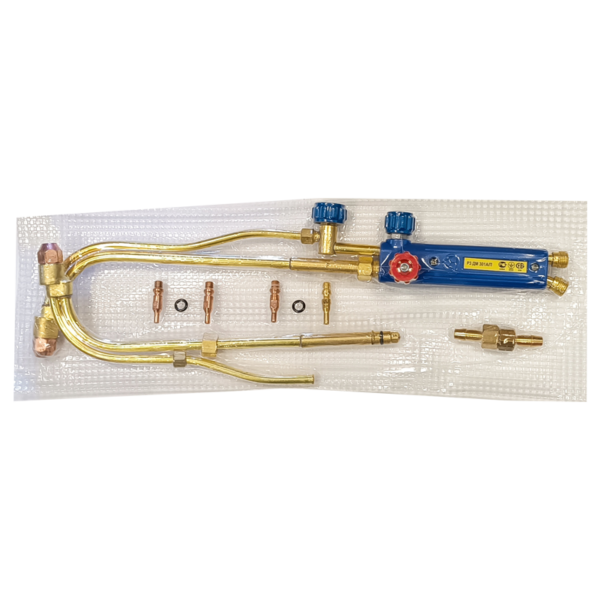

– cutting torch with in-nozzle gas mixing KFR-352-15/16/17 with an attachment for supplying flux;

– three gas-feeding rubber-fabric hoses (9mm);

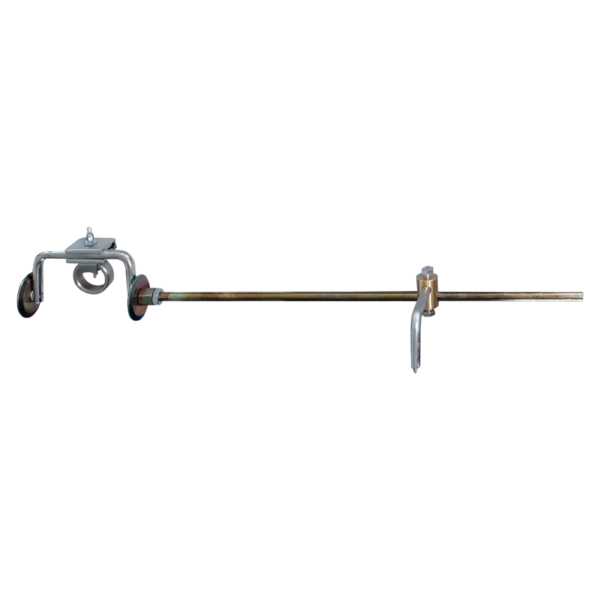

– cart with an attachment;

– propane pressure regulator.

The basis of all fluxes for oxy-flux cutting is iron powder that in most cases is used just as it is, especially for cutting steel and grey iron.