Designed for: machine parting cutting of low-carbon steel 300 to 800 mm thick (ingots, forged pieces, etc.).

It has been successfully used at such enterprises as PJSC “Energomashspetsstal” and PJSC “ArcelorMittal Kryviy Rih”.

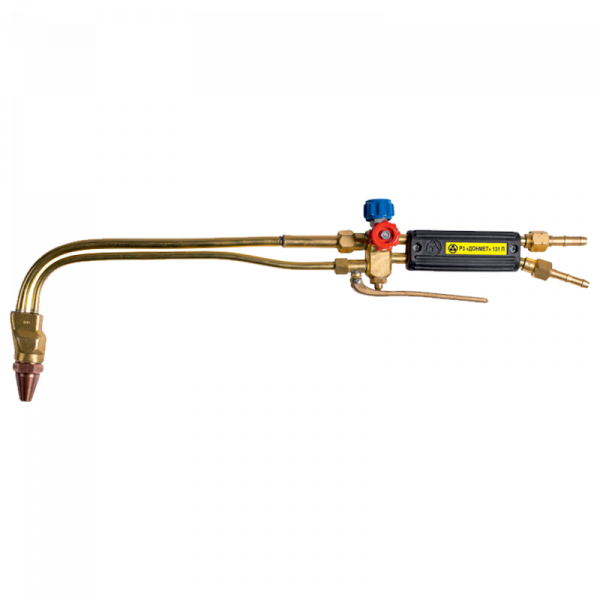

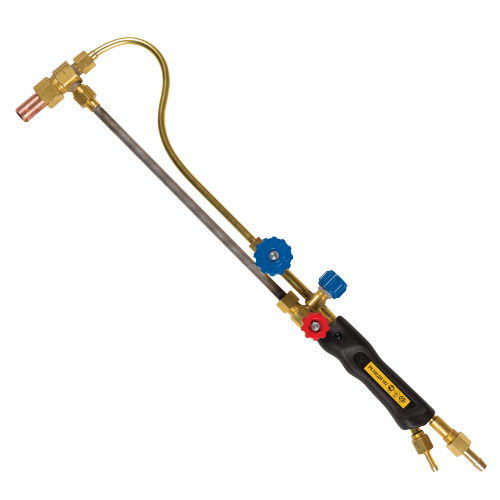

The cutting torch’s most distinguishing feature is external gas mixing that happens outside the nozzle which makes backfires impossible.

Design features: separate feed channels for cutting oxygen and preheating oxygen; gas consumption adjustment via the gas-cutting machine control panel.

Used gas fuel: natural gas (methane).

The delivery set contains nozzle No. 800 (order No. 511.001.00). As per customer’s order the cutting torch can be supplied with nozzles No. 300 (order No. 511.001.01) and No. 500 (order No. 511.001.02).

TECHNICAL SPECIFICATION

| Cutting thickness, mm |

300 |

500 |

800 |

| Nozzle No. |

300 |

500 |

800 |

| Speed of cutting, nominal, mm/min. |

140 |

90 |

65 |

| Width of cut, nominal, mm |

10 |

20 |

30 |

| Inlet pressure cutting oxygen, bar |

6 |

6 |

7 |

| Inlet pressure preheating oxygen, bar |

1,5 |

2 |

2,5 |

| Inlet pressure natural gas (methane), bar |

0,8 |

0,8 |

0,8 |

| Consumption cutting oxygen, m3/h |

30 |

80 |

170 |

| Consumption preheating oxygen, m3/h |

15 |

28 |

33 |

| Consumption natural gas (methane), m3/h |

15 |

27 |

32 |

| Hose inner diameter, mm |

12 |

12 |

12 |

| Cutting torch length no more than, mm |

1050 |

||

| Cutting torch weight no more than, kg |

3,0 |

||

| Connection unit thread diameter cutting oxygen |

М20х1,5 |

М20х1,5 |

М20х1,5 |

| Connection unit thread diameter preheating oxygen |

М20х1,5 |

М20х1,5 |

М20х1,5 |

| Connection unit thread diameter gas fuel |

М20х1,5LH |

М20х1,5LH |

М20х1,5LH |